5TD/5TS-Series Drive Bucket Elevator

Keywords:

E-mail us:

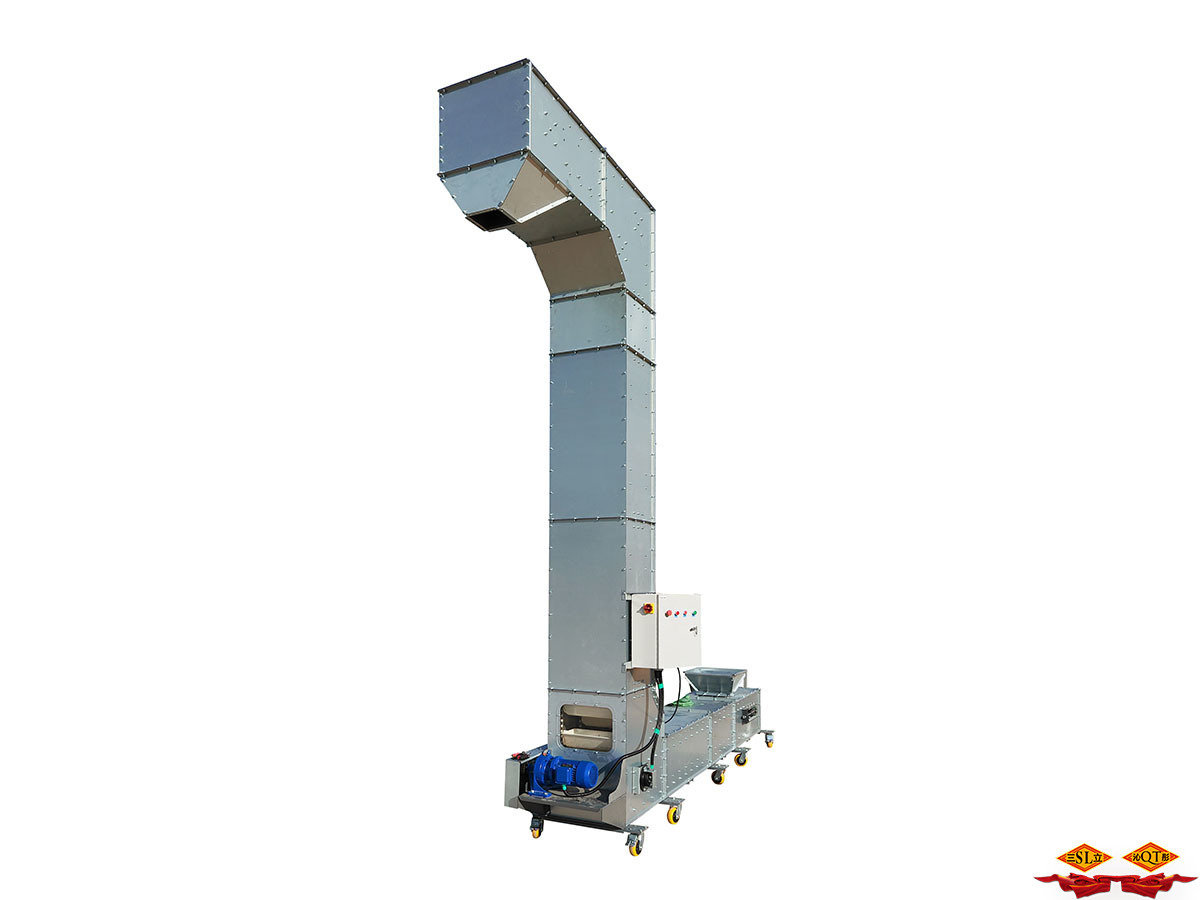

5TD/5TS-Series Drive Bucket Elevator

The drive type bucket elevator is a conveyor that transports materials through bucket suspended on chain inside a closed barrel. It can achieve horizontal, vertical, and horizontal combined conveying, and can feed at single or multiple points. Single or multiple point discharge can be completed through the unloading device, and it is fully enclosed without leakage.

Suitable for conveying various powdered and granular materials. The combination form of this machine is flexible, with extremely low material damage rate, suitable for various work scenarios that require gentle handling of materials.

Multiple combination types. Multiple feeding and discharging methods.

● No material breakage or damage during the transportation process.

● It can be designed as Z type, C type, T type according to customer needs.

● Single or multi-point feeding, single or multi-point unloading.

● Leak free compact buckets.

● Standard high-quality nickel plated chain, corrosion-resistant and low wear.

● Modular design, horizontal segment length and vertical segment height can be customized according to user requirements.

● Equipped with a torque limiter, in case of unexpected malfunctions during operation, the torque limiter will protect the machine from damage and automatically shut down.

● Compact structure and small footprint.

● Energy saving, environmentally friendly, easy to install and maintain.

Model | Capacity | Height | Power | ||

Full-bucket | 70%-bucket | Wheat seed | |||

5TD-06 | 6 m3/h | 4.2 m3/h | 3.1~3.5 t/h | 2~15 m | 0.75kW |

5TD-15 | 15 m3/h | 10.5 m3/h | 7.5~8.5 t/h | 2~25 m | 0.75~1.5kW |

5TS-15 | |||||

5TS-20 | 20 m3/h | 14 m3/h | 10.5~11.2 t/h | 2~25 m | 0.75~1.5kW |

5TS-30 | 30 m3/h | 21 m3/h | 15.5~16.8 t/h | 2~25 m | 2.2~3kW |

5TS-40 | 40 m3/h | 28 m3/h | 21~22.4 t/h | 2~25 m | 2.2~3kW |

Noted: The wheat seed lifting capacity is converted based on a bulk density of 750~800 Kg/m3.

Working Principle..

When elevator is working, the reduction motor drives two chain wheels to move synchronously through bearings, thereby causing the two chains to move synchronously on the track.

The material falls into the horizontal forward buckets through the feeding hopper. As the material slides into the buckets instead of being forcibly scraped, it will not cause the material to break.

The synchronous movement of the two chains causes the buckets between them to continuously move on its track. The transition between horizontal and vertical conveying is accomplished by two sets of pulley units located at the upper and lower corners;

The material is transported to the discharge port or the middle discharge port, and the special shaped guide rail of the discharge port raises the guide pin of the bucket, causing the bucket to tilt and empty the material.

Model Selection Notice..

Related products

INQUIRY

MOBILE SITE

Sanli Grain Sorting Machinery

Tel: +86-311-87711446 Fax: +86-311-66635737

E-mail: marketing@sanli.net.cn

Wechat: 15032818070

Factory Add: No.68 Airport Road, Development Zone of Xinle, Shijiazhuang City, Hebei province, China

Network Security Manager:Wengang Wei

Copyright © 2022 Sanli Grain Sorting Machinery Co, Ltd.